E-commerce

Anycubic Kobra Review: The Best Budget 3D Printer?

Table of Contents

What is Anycubic?

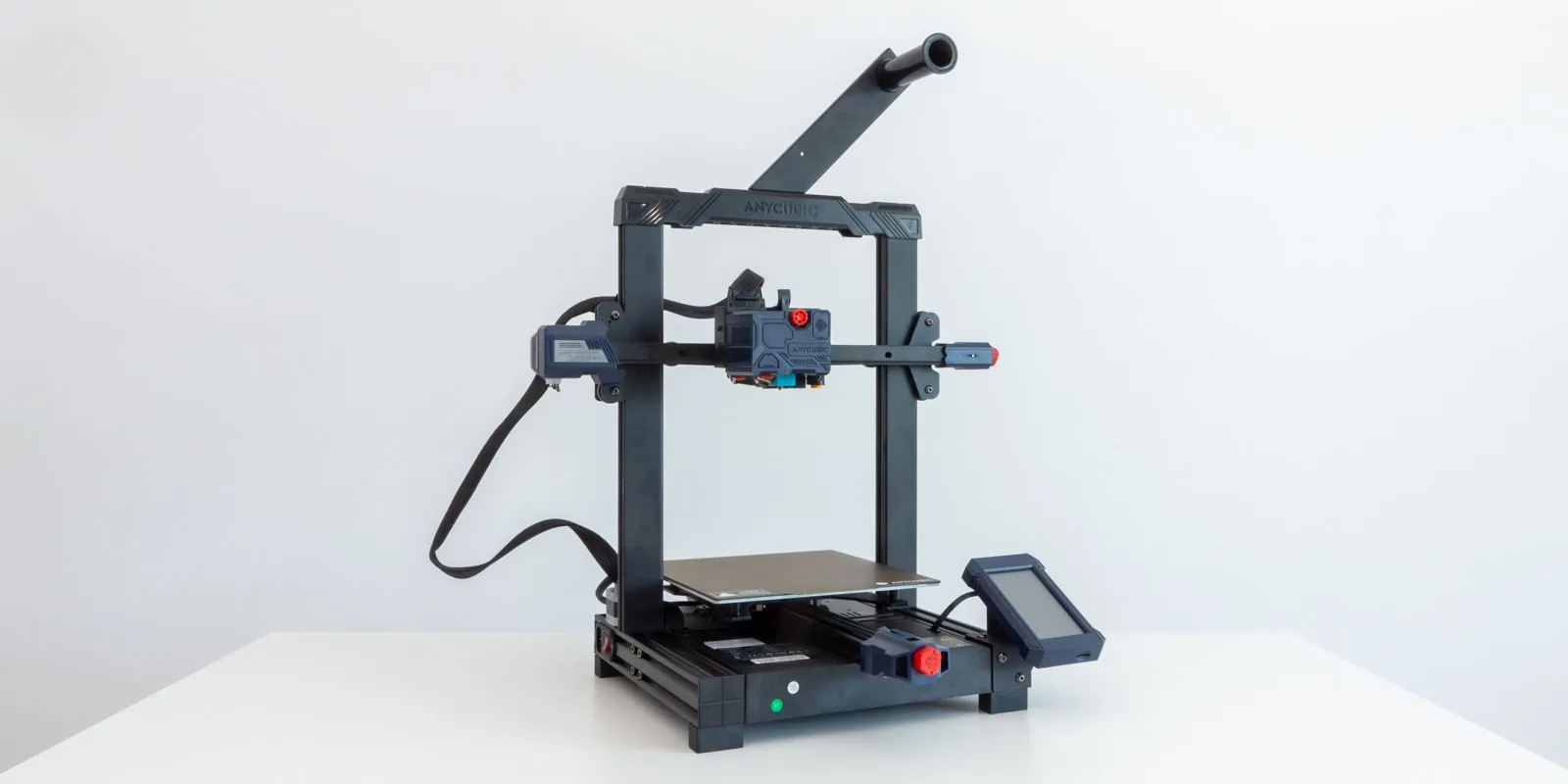

It is no secret that Anycubic makes some of the most popular 3D printers on the market. The Kobra is one of their newest models, and it has quickly become a favorite among budget-conscious buyers. So, what makes it so special?

For starters, the Kobra comes with a long list of features, including automatic bed leveling, a removable PEI coated print bed, sensorless homing, and a 220x220x250 mm print volume. But does it perform as well as it promises?

In this Anycubic Kobra 3D printer review, we will test whether it lives up to its specifications and see how it compares to similar 3D printers on the market today.

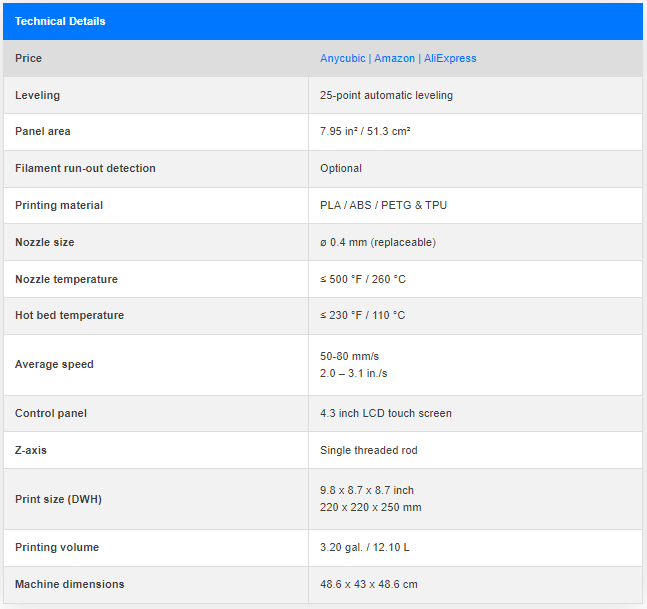

Anycubic Kobra Specifications

Printing Technology

The Anycubic Kobra is a fused deposition modeling (FDM) 3D printer. This technology uses a filament, which is melted and extruded through a nozzle onto a build platform.

FDM 3D printers are popular because they are relatively inexpensive, and the prints produced are strong, accurate, and affordable.

This 3D printer is no exception. As you will see in this Anycubic Kobra review, the machine is capable of producing excellent results with a variety of 1.75mm filaments, including PLA, ABS, and PETG.

Anycubic Kobra Unboxing

Like many other hobbyist 3D printers, the Anycubic Kobra is shipped flat-pack style. This helps save shipping costs but does require you to do some assembly before you can use the 3D printer.

The first thing you’ll notice when opening the Anycubic Kobra’s packaging is the 3D printer’s surrounding foam protection. All parts are well-protected and it is unlikely that you will encounter damage from the shipping process. Remove the contents from the box and you will find the components of the Anycubic Kobra along with its accessories.

The accessories are similar to what comes with other FDM 3D printers nowadays. You get all the tools for assembly, like Allen keys and wrenches, but also includes several accessories for the actual use of the 3D printer.

Here you can think of a small pair of snippets to cut filament, a plastic scraper for print removal, and a nozzle cleaning tool for unclogging the nozzle when necessary.

For maintenance purposes, you get a small tube of grease, an extra PTFE tube, and a spare nozzle. These are both quite generic in terms of quality, but you can’t really expect more for a 3D printer under $300. Also included is a small spool of PLA filament. While it is generic white PLA, this is a nice little extra from Anycubic.

Do keep in mind that it is only 35 grams of filament. This allows you to start printing right away, but it will run out quickly. It was enough for a couple of test prints for this Anycubic Kobra review, but that was about it.

That said, the Anycubic Kobra box contents are more than sufficient for a 3D printer at this price point. And if this is your first 3D printer, you will have everything you need to get started 3D printing right away.

Getting Started with the Anycubic Kobra 3D Printer

While the Anycubic Kobra 3D printer comes mostly pre-assembled, there is still some assembly required.

If you have any experience with 3D printers or any other electronic device that requires some level of assembly, the Anycubic Kobra will be a breeze to put together.

Even if this is your first time assembling a 3D printer, the manual does a good job of walking you through the process step-by-step. In fact, the manual is quite clear and a step above that of several other popular 3D printers that we have assembled. Overall, you can expect this process to take about 15-20 minutes of your time.

Anycubic Kobra Features

Unlike other budget 3D printers, like the Ender 3 v2, the print bed of the Anycubic Kobra does not offer adjustment nuts for bed leveling. This is because the Kobra comes with an inductive probe that is able to detect the exact position and slope of the bed and adjust for it in software.

Inductive probes are a nice feature to have as they make the bed leveling process much simpler and more accurate. They work by creating a magnetic field and detecting changes in it caused by nearby metals.

Because the Anycubic Kobra uses a spring steel bed, the inductive probe can detect its position with ease and accuracy. However, if you will ever switch to a glass print bed, this sensor will not be able to detect it.

Non-contact inductive probing is a different process than with the BLTouch and CRTouch sensors that physically probe the bed. We have found either probe type to be accurate enough for getting that perfect first layer, but with the inductive probe undergoing less wear and tear over time as it has no moving parts.

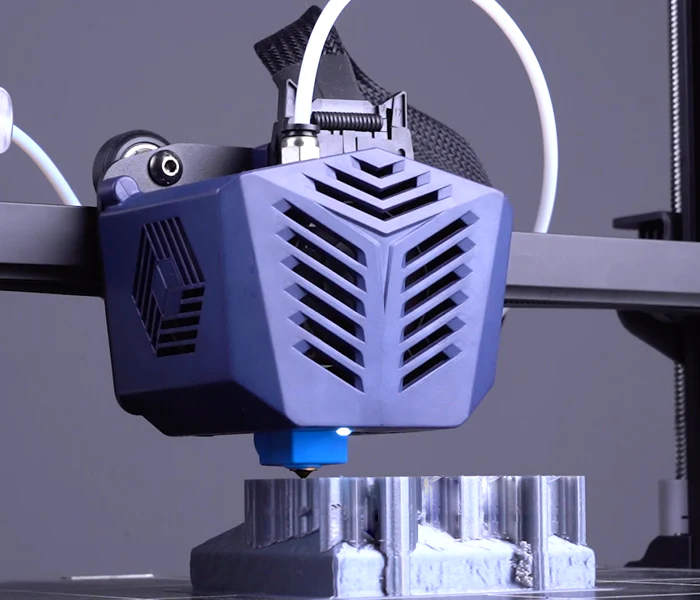

The Anycubic Kobra uses a direct drive extruder. This means that, in contrast to a Bowden extruder, all print head components are located in the same space as where the filament exits the nozzle. This is an improvement over Anycubic’s last year’s release, the Anycubic Vyper, which uses a Bowden extruder.

Electronics

The Anycubic Kobra is controlled by a TriGorilla Pro A V1.0.4 motherboard. It comes with an HC32F460 ARM Cortex-M4 32-bit processor and silent TMC2209 stepper motor drivers. TriGorilla boards are also used on a number of other Anycubic 3D printers, and it is unlikely that you will run into issues that won’t get resolved with a firmware update.

The 32-bit processor means that the Anycubic Kobra is capable of faster print speeds than other budget 3D printers (with 8-bit motherboards). At the same time, the processor will have enough power to support new and exciting firmware features that might be released in the coming years.

As for the stepper motor drivers, Anycubic has chosen to use TMC2209 drivers from Trinamic. The TMC2209 is a very popular choice for 3D printer builders as it is reliable, drives stepper motors silently, has thermal protection, and offers sensorless homing capabilities.

These silent stepper motors are a welcome upgrade from any previous machines we have used, as they tend to be much quieter and make fewer vibrations when you home your printer or do any 3D printing.

All of these features help to ensure that the Anycubic Kobra 3D printer will likely work reliably for many hours at a time without problems.

Do keep in mind that the stepper drivers are soldered directly to the board. This is not a problem in itself, but if any of the drivers ever need to be replaced, it will require some soldering skills to do so.

This is not something that you ever need to do in normal circumstances, but if you happen to unplug one of the stepper motors while the 3D printer is powered on, there is a good chance of burning its connected driver and causing the need for its replacement.

Anycubic Kobra Build Quality and Construction

The overall build quality of the Anycubic Kobra 3D printer is solid. It uses metal parts for the most important components, adding up to a sturdy machine that does not feel flimsy.

There are some parts that could have been made from metal to improve its rigidity further, for example, the horizontal brace on top of the vertical arms of the frame.

Along with its other prominent injection-molded components, like the extruder cover and belt tensioners, this does cause the machine to have a bit of a plasticky feel to it.

In that sense, the Anycubic Kobra is comparable to the Artillery Genius Pro, which takes a similar approach with its parts. In the end, however, cost wins over form and we would rather have a machine that is a little less rigid but also significantly cheaper.

Single Z-Axis Lead Screw

We would have also liked to have seen a second stepper motor and lead screw on the Z-axis. The direct drive extruder weighs in at about one pound (half a kilo) and throws a lot of mass around at maximum printing speed.

A second Z-axis lead screw would have helped to mitigate any Z-banding and ringing that might occur due to the weight of the extruder, resulting in better print quality.

The design team at Anycubic might agree with us on this one, but they probably decided to forego a second Z-axis motor in favor of keeping the machine as affordable as possible. This is a reasonable decision and one that we can respect.

While we did not notice any issues from the 3D printer only having one Z stepper motor and lead screw right now, we can’t help wonder whether this will still be the case after the machine’s components start to develop more wear and tear from regular use.

Ease of Use

The stock firmware on the Anycubic Kobra 3D printer is fairly limited. If you are looking for in-depth control of print settings, stepper motor parameters (current, micro-steps), or other advanced functionality like setting the maximum acceleration, you will need to do it through G-code.

However, all required basic print settings are there. Configuring the settings for the nozzle temperature, bed temperature, or bed leveling are all available where you’d expect them to be.

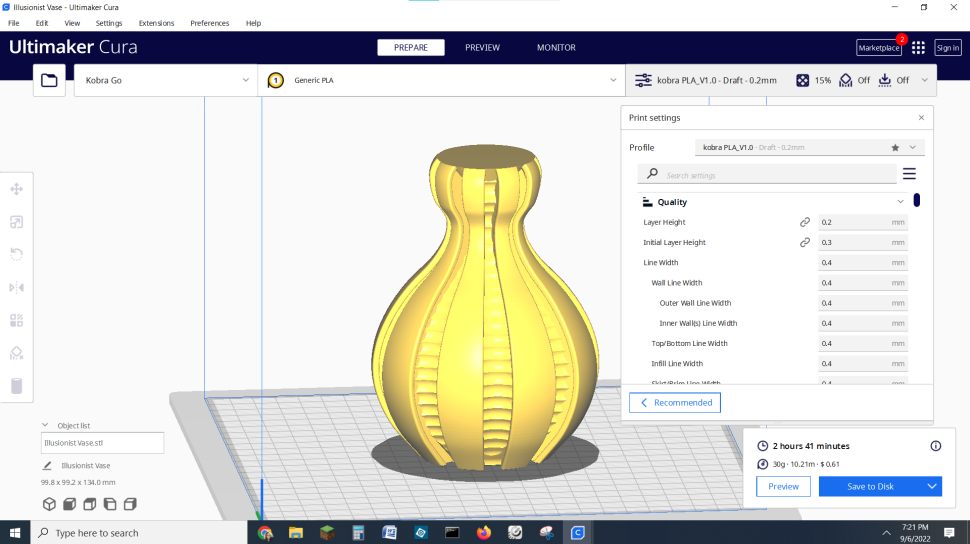

The Anycubic Kobra ships with a copy of Cura slicer on its SD card, but we should point out that our included Cura version was outdated (4.2.1). It also did not come with a preconfigured profile for the Anycubic Kobra.

This might be changed in the future, and you should make sure to update to the latest version of Cura (or your preferred slicer) regardless. If the slicer does not come with a profile for the Kobra, you will have to set up your own profile to get the best out of the 3D printer.

Testing Data

The Anycubic Kobra offers good quality at a normal print speed of 50-60mm/s. Compared to the Kobra Max and Vyper, which both have a Bowden extruder, the Kobra comes with a maximum print speed of 100mm/s instead of 180mm/s.

This is understandable, because the Kobra comes with a heavy direct drive extruder. This makes achieving high print speeds more difficult without losing print quality.

At 60mm/s print speeds, we did not experience any quality problems like ringing or ghosting. However, if your priority is to decrease 3D print time and increase your 3D printing output, one of the other 3D printers listed above (which come with an 80mm/s recommended average speed) or even a CoreXY 3D printer is likely to be a better option for you.

Compared to other 3D printers, the Anycubic Kobra is rather loud. Both the electronics compartment fan and power supply fan have been selected for their high airflow to cost ratio, and as a result they aren’t shy of letting themselves be heard.

Anycubic Kobra Print Quality

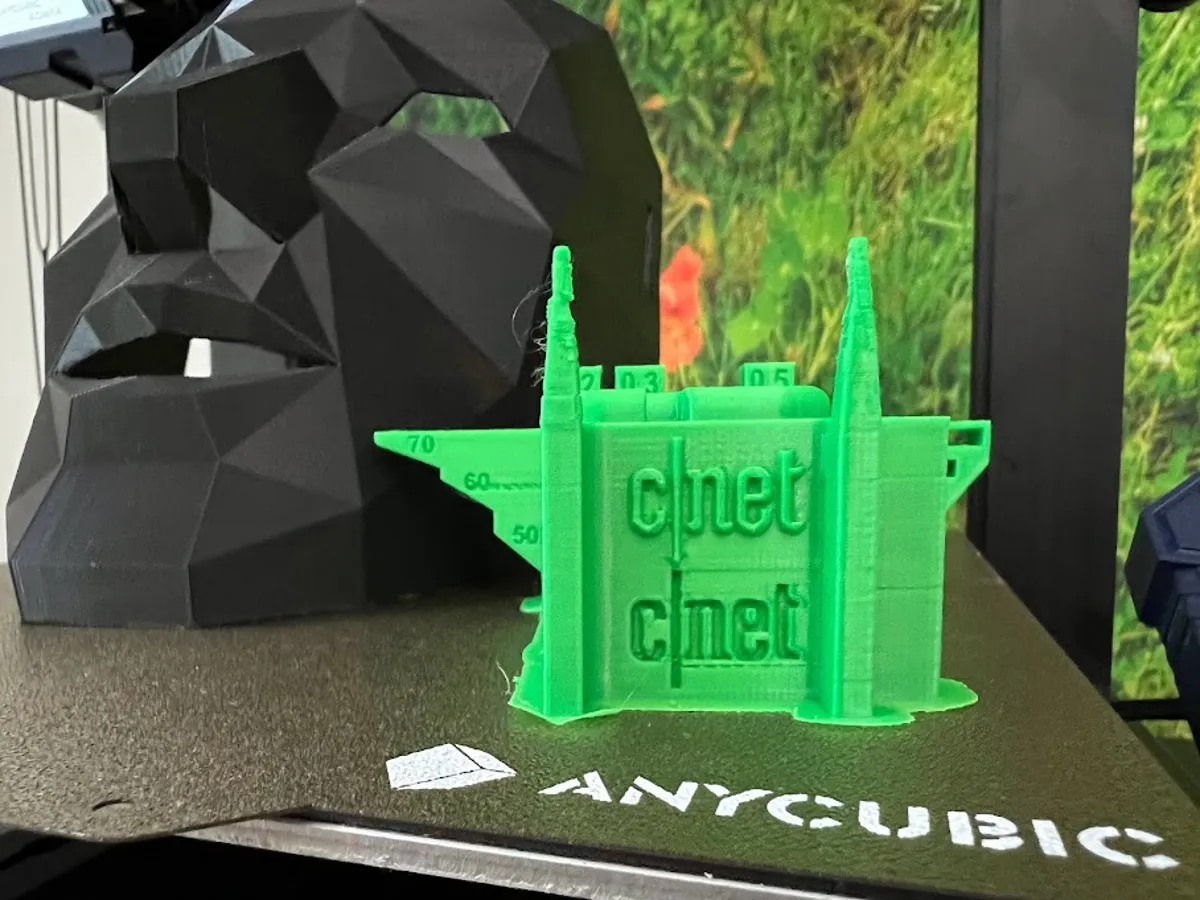

It wouldn’t be an Anycubic Kobra review if we didn’t cover the print quality. The Kobra does not disappoint in this area and provides excellent results for its price. We were able to get some very nice-looking prints out of it, with smooth surfaces and well-defined details.

All test prints below were made with the Cura filament setting profiles that came with the Kobra, aside from the PETG print. No PETG profile was included, so we used our stock PETG settings.

There is some drooping of filament in several areas, however, likely due to the underpowered print cooling fan. This can be prevented by increasing the minimum layer time or decreasing print speed.

Compared to Other 3D Printers

Anycubic released the Vyper in 2021, one year before the Kobra. Both printers share a number of similarities, but Anycubic has made a couple of (in our opinion) improvements to the Kobra that make it a better 3D printer.

In terms of differences, the Anycubic Kobra comes with a direct drive extruder instead of the Vyper’s Bowden extruder. This means that the extruder of the Kobra can offer better print quality but at a cost of a decreased maximum print speed.

At the same time, the build volume of the Kobra is smaller than that of the Vyper. The Kobra has a print volume of 220x220x250 mm, whereas the Vyper offers you 245x245x260 mm.

Both 3D printers support auto bed leveling, but where the Vyper uses a strain gauge, the Kobra uses are more reliable inductive sensor.

Most other major features are the same. Hot end temperature and print bed temperature are identical, so the range of supported filament is that as well. Both the Kobra and the Vyper have a PEI coated spring steel bed, and they offer the same bed adhesion.

Electronics and the touchscreen are practically identical too, even though the Kobra has a newer Cortex-M4 processor instead of the Vyper’s Cortex-M3. In practice, you are unlikely to notice the difference.

After making our Anycubic Kobra review, the only reason we can come up with to choose the Vyper over the Kobra (discount offers aside) is to take advantage of its increased build volume. However, if that is what you are looking for, you might be better off with the Anycubic Kobra Max instead.

Verdict: Should You Buy the Anycubic Kobra?

After testing and comparing the Anycubic Kobra and ultimately creating this Anycubic Kobra review, we can confidently say that it is the best 3D printer under $300 at the moment.

The Kobra offers good print quality and premium features like sensorless homing and auto bed leveling to get a perfect first layer each time. Its PEI print surface gives excellent bed adhesion to any filament, and because it is flexible, you can bend it to pop your 3D prints off.

As potential downsides, the Kobra comes with a loud electronics cooling fan, sometimes finicky filament loading, and it is not very configurable in terms of the firmware.

However, at its current $299 cost it stands out above similar printers in its price range, like the Artillery Genius Pro and Creality Ender 3 V2.

The Kobra even can even match up against the Creality Ender 3 S1, even though the latter has several quality-of-life features that can be worth the extra $100 for some.

In short, if you are looking to get into 3D printing or you already are a 3D print aficionado on a budget, the Anycubic Kobra is going to give you a printing experience worthy of your money.